Accelerating Quality Ops with Precision Indoor Vehicle Tracking

Overview

At one of Canada’s largest automotive manufacturing facilities, precision isn’t optional – it’s the driving force of producing 1,200 vehicles every single day. With thousands of moving parts, people, and processes, even the smallest inefficiency in vehicle tracking can ripple into millions in costs, delayed throughput, and reduced customer satisfaction. Partnering closely with plant leadership, our team implemented a cutting-edge real-time indoor vehicle tracking solution that completely redefined how vehicles are located and managed across end-of-line (EOL) production, staging, and quality workflows.

The Challenge

Before our deployment, when vehicles were placed under quality hold, locating them was a time-consuming, manual process. Teams relied on outdated printed worksheets, long facility walks, and guesswork, adding an extra 15 minutes per car on average — a drain on productivity that created bottlenecks in a plant designed to run like clockwork. The result: costly delays, mounting inefficiencies, and an unnecessary strain on logistics precision.

Time-consuming vehicle location for almost all quality and repair operations (~700 pickups/month per line)

Inefficient handoff processes between the quality pickers and high-cost repair laborers

Costly labor and overtime for vehicle retrieval, staging, and movement

Inability to pinpoint location of vendor-damaged vehicles impacting cost recovery

The Solution

Our advanced indoor location platform was deployed across both production lines, strategically covering high-volume traffic zones and integrating seamlessly into existing plant operations. With vehicle locations now tracked with pinpoint accuracy, the plant can instantly locate and redirect assets, ensuring smooth flow through every stage of the production and quality cycle.

Precision indoor location with 3–5 meter average accuracy

Seamless support for vendor defect tracking and quality control workflows

Validated technology that scales in real-world OEM environments

Proven performance in OEM’s harsh RF/metal-dense conditions

The Results

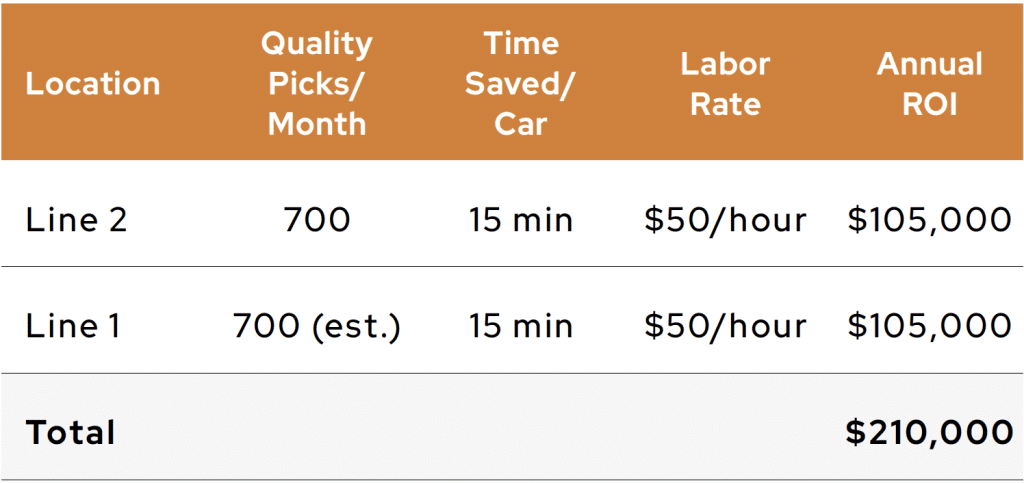

Even with ROI calculated strictly in time savings, the value is undeniable:

When factoring in broader operational gains, the leadership team conservatively estimated a > $300,000 annual return.

Additional high-value benefits:

Faster throughput and plant velocity 1200 vehicles/day*~300 days*~$30k vehicle cost

Decreased dwell time and shipping delays

Improved vendor accountability and cost recovery for defective parts

Enhanced transparency for inventory management

The impact

This isn’t a “nice-to-have” technology – it’s a necessary game-changer. By eliminating hours of manual searching and replacing guesswork with real-time intelligence, the plant unlocked measurable ROI from day one. The solution not only streamlines daily operations, but also provides the scalability and agility OEMs need to future-proof manufacturing against shifting demands. It’s proof that digital transformation delivers real, tangible impact on the factory floor.

The impact

With the foundation now in place, the facility is expanding the system’s reach — exploring deeper analytics, strategies to reduce dwell time, and enhanced operational workflows that will drive even greater speed, accuracy, and profitability across the entire manufacturing ecosystem.

Quality management

Cognosos location intelligence for vehicles

Discover how you can leverage real-time vehicle visibility and driver insights to significantly drive down costs and boost efficiency.