Drive better outcomes through real-time visibility and process analytics across your supply chain

From plant floor to port — and every mile in between

Process improvement driving meaningful results

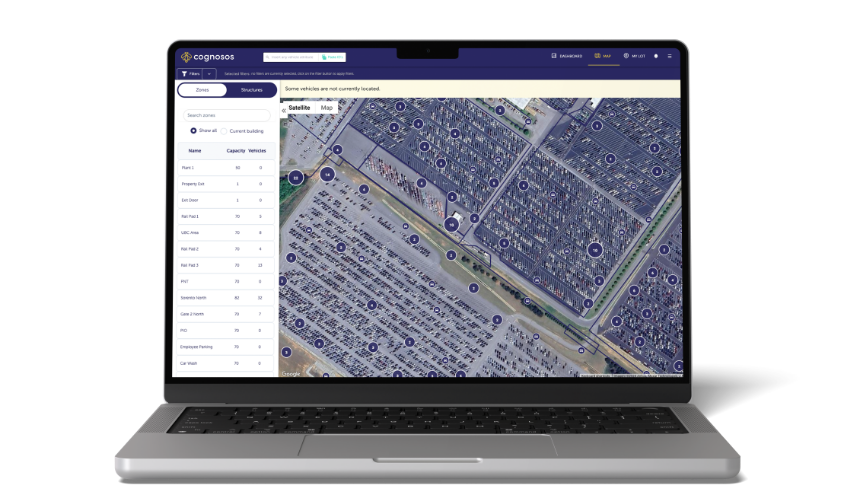

In today’s complex automotive logistics landscape, real-time visibility isn’t just a convenience — it’s a competitive advantage. Cognosos delivers a powerful, unified platform that gives OEMs, upfitters, and logistics providers unprecedented insight into the movement and status of assets enabling data-driven decisions to increase throughput.

92%

Reduction in avg. vehicle location times

26%

Reduction in vehicle moves per repair

5%-10%

Reduction in dwell time

77%

Reduction in quality campaign durations

Real-time intelligence at every stage

Track the movement of passenger vehicles from end-of-line through yard operations with precise location updates. Eliminate lost time searching for vehicles, reduce dwell time, and ensure timely carrier handoffs.

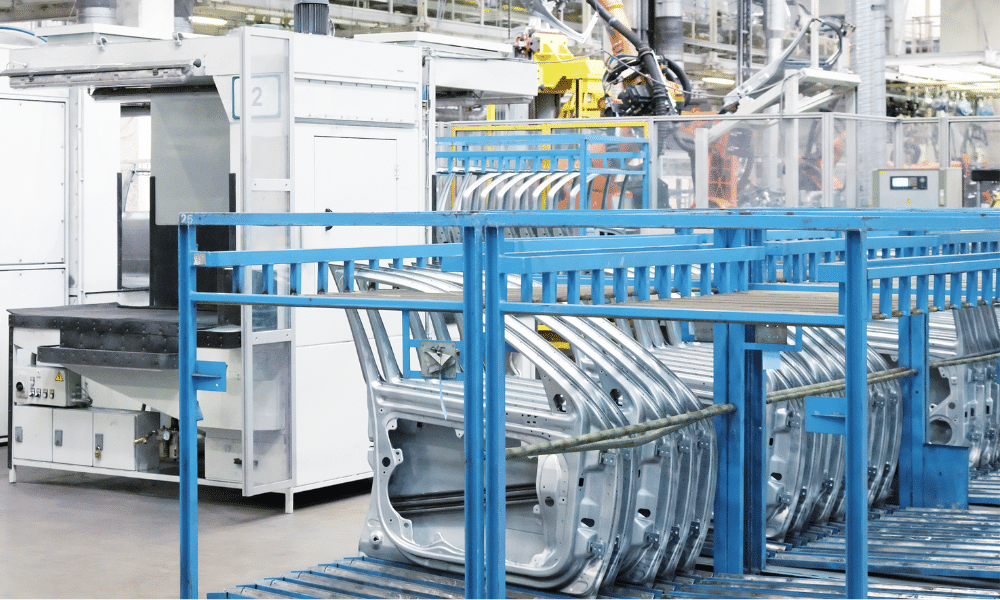

Offline & post-production quality management

Gain complete visibility into vehicles undergoing offline inspection, rework, or post-production customization. Never lose track of a vehicle in transition again.

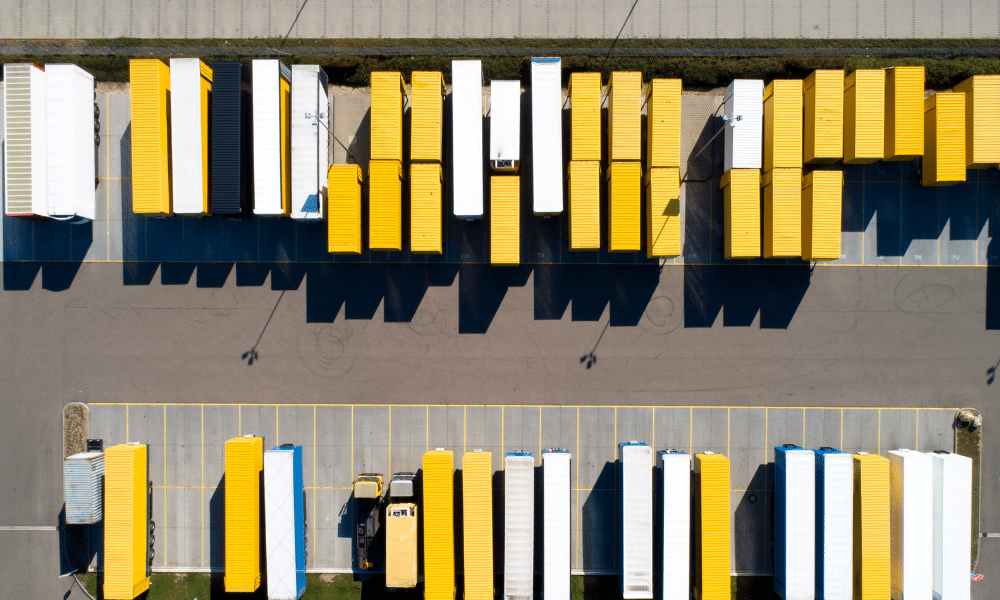

Inbound logistics & trailer tracking

Monitor trailer arrivals, departures, and dwell times across your manufacturing facilities. Ensure the right components arrive on time, every time.

Returnable transport items (RTIs) Tracking

Track RTIs, racks, and production containers across plants and yards. Reduce loss, increase turnaround speed, and keep your production line moving.

Automobile Auctions

Eliminate wasted time searching for vehicles. Gain real-time visibility into every vehicle on the yard, and ensure vehicles are in the proper lanes ahead of sale day.

Automotive upfitter operations

From delivery vans and box trucks to utility and field service vehicles, keep assets flowing through upfit facilities, identify delays in real time, and maintain alignment across internal and third-party teams.

Supply chain actionability

Protect what matters most across your supply chain with real-time asset-level visibility and chain-of-custody visibility from origin to destination.

The power of real-time visibility

Cognosos incorporates widely available technologies like GPS and Bluetooth, and applies its proprietary LocationAI platform to deliver highly accurate locations through an ultra-light infrastructure

Improve decision-making

with up-to-the-minute location and status data.

Proactively manage bottlenecks

before they impact operations.

Keep ecosystem partners informed

and aligned through shared visibility.

Significantly Increase throughput

by reducing search time, cycle time, and loss events.

Built for scale. Proven in Automotive

Trusted by global OEMs, Tier 1 suppliers, and logistics providers, Cognosos brings the speed, precision, and flexibility needed to support the full vehicle and component lifecycle — from raw materials to final delivery.

Your success is our mission

Customer stories

We are dedicated to ensuring that our customers achieve their goals and realize the full value of real-time visibility. Discover how businesses like yours have achieved success with our AI-powered location intelligence.

Case Study

Accelerating quality ops with precision indoor vehicle tracking

Case Study

How a vehicle manufacturer boosted efficiency with real-time tracking

logistics

Cognosos location intelligence

Discover how you can leverage real-time visibility and driver insights to significantly drive down costs and boost efficiency.

Request a demo

Logistics Solution FAQs

Why can’t we hit our vehicle throughput targets even when we add more staff?

More people doesn’t fix broken processes. When drivers spend 30-40% of their time searching for vehicles instead of moving them, adding staff just means more people searching. The bottleneck isn’t labor, it’s visibility.

Finished vehicle logistics solutions eliminate search time entirely. Drivers get guided directly to vehicles, complete more moves per shift, and you finally see which processes are actually slowing you down.

How long does it really take to find vehicles on quality hold?

Most facilities estimate 15 – 30 minutes. The reality? When vehicles are randomly parked across massive yards or multiple satellite locations, technicians can waste half a day or more tracking down a single VIN. Your repair bays sit idle while skilled labor searches.

End of Line quality management shows the exact location of every quality hold vehicle in real time whether it’s inside or outside. Technicians go straight to work, repair bays stay busy, and you finally get data on what’s actually extending your quality campaigns.

Why do trailers keep disappearing or sitting idle for days?

Without real-time visibility, trailers become invisible assets. They get dropped in random spots, borrowed by other departments, or sit forgotten while you rent additional units to meet demand. Manual yard checks only show you a snapshot, not what’s been happening all week.

Trailer yard visibility tracks every trailer’s location and dwell time automatically. You know which trailers are available, which have been sitting too long, and where assets are when you need them.

What’s causing delays in our upfitter operations?

When chassis arrive from OEMs, speed matters. But upfitters typically work across multiple satellite yards miles apart. Hours get wasted figuring out which yard has the chassis you need, then finding it within that yard. Throughput suffers and inventory financing costs pile up.

Vehicle upfitter solutions give you real-time visibility across all locations. Find chassis instantly, move them through conversion faster, and reduce the inventory buffers you built to compensate for lost time.

How do we stop missing vehicles from auction day lineups?

The scramble to get all vehicles in their assigned lanes before auction starts is chaotic. Vehicles get misplaced, moved to wrong areas, or buried behind other inventory. Every vehicle that misses its slot is lost revenue.

Auto auction solutions use geofencing to track lane assignments automatically. You get alerts about vehicles not in position, unauthorized moves, and cars at risk of missing their slots. Stop firefighting on auction day.

Why are we constantly buying new returnable containers?

Containers disappear into yards, get borrowed by other facilities, or sit forgotten in corners while you order replacements. Without visibility into where containers are and how often they’re actually used, you can’t tell if you’re short on inventory or just bad at finding what you have.

Returnable container tracking shows every container’s location across all your sites, indoors and out. Understand true inventory needs, reduce replacement costs, and stop wasting time crawling around looking for misplaced units.

What’s actually happening inside our plant between first roll and shipping?

The “offline” period when vehicles move through quality checks, repairs, and prep is a black hole. You know vehicles go in and eventually come out, but you can’t see bottlenecks, process deviations, or why some vehicles take three times longer than others.

Offline vehicle visibility tracks every vehicle from first roll through the entire plant. Identify bottlenecks before they impact targets, ensure process adherence, and maximize throughput with complete visibility into your hidden factory.