How a Vehicle Manufacturer Boosted Efficiency with Real-Time Tracking

A North American vehicle manufacturer’s truck assembly plant was grappling with inefficiencies in post-assembly quality due to manual processes causing extended search times and productivity issues. The manufacturer adopted Cognosos’ real-time vehicle tracking technology to streamline and enhance the repair quality and process.

Their Business Challenges

- High volume: Over a hundred vehicles were awaiting repair at any given time, causing congestion alongside fully assembled trucks.

- Manual tracking: The manufacturer relied on printed lists and colored tags, involving VIN comparisons for locating vehicles.

- Extended search times: Metrics consistently indicated prolonged and unpredictable durations for vehicle location, impacting overall efficiency.

- Productivity impact: ‘Time to locate’ and ‘mean time to repair’ metrics suffered, disrupting repair station operations.

- Operational disruptions: Repair stations occasionally paused work, awaiting delivery of specific vehicles, further hampering productivity.

Cognosos Solution Implementation

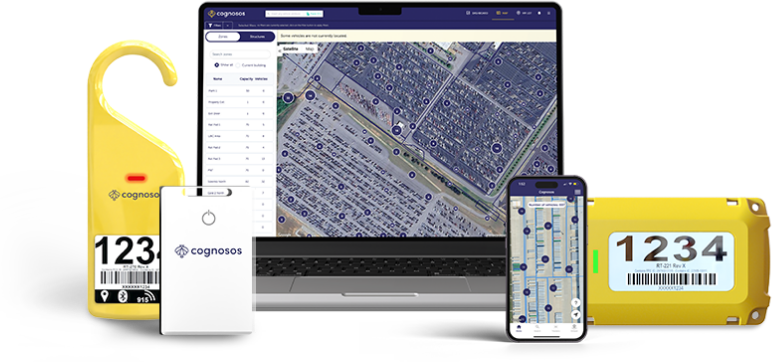

- Equipment: Encompassing 2,000 GPS tracker tags, ‘Gateways’ acting as routers with long-range antennae, and ‘Activators’ providing location data in GPS-challenged environments.

- Software: Featuring smartphone apps for Apple and Android, the Cognosos portal for dashboard access, a Cloud data repository, web-based reporting applications for thorough data analysis, and REST APIs for seamless data exchange with the manufacturer’s enterprise systems.

- Support: A dedicated project manager and support provider serving as the director of customer field operations, available customer operations engineers, and unlimited access to Cognosos’ support team via email or phone.

Impact & Results

What was the Impact?

Estimated $500K reduction in costs

20% reduction in vehicle moves per repair

5-10% reduction in dwell time

Reduction in time to repair metric

An Ongoing Partnership

In response to post-pandemic automotive component shortages and a rise in the ‘build-shy’ ratio, the truck assembly plant extended the Cognosos solution to track both ‘build-shy’ vehicles and their required components, leading to a broader implementation across the plant’s finished vehicle logistics operations and remote storage yards.

Request a demo

Cognosos utilizes the power of AI/ML to transform tracking data into operational intelligence, redefining the value of location solutions. Cognosos is able to quickly deploy with an ultra-lightweight footprint that excels in complex environments, producing a hard-dollar ROI within months through a subscription based service model.