Environment

Hospital Refrigerator and Freezer Temperature Monitoring System Solutions

Ensure Compliance, Eliminate Manual Temperature Checks, and Prevent Costly Spoilage

Temperature monitoring that alerts you in real time and keeps audit logs ready. Your medications and samples stay protected while your staff stops having to do manual rounds.

- Simplify JCAHO, CDC, DNV, and VFC compliance

- Enterprise-wide intelligence with automated reports and customized alerting

- Wireless architecture with NIST traceable calibration

Automate Manual Tasks with Cognosos Environment

Experience a hospital refrigerator and freezer temperature monitoring system that replaces manual checks with real time alerts and audit ready logs. Pharmacy, labs, and blood bank teams see issues early and act fast.

- Monitors and logs environmental conditions readings 24/7.

- Verifies in-range, at risk, and out-of-range inspections so corrective action can be taken quickly.

- Identify problematic areas, devices, or conditions.

>$20M

In annual product loss across US hospitals due to improper refrigeration

CDC

Reduce spoilage

Save money by reducing loss of critical medications and medical supplies.

Reduce infection risk

Proper temperature monitoring helps stifle bacteria and associated infection risk.

Minimize staff burden

Eliminate staff time spent doing manual temperature checks, freeing up personnel for patient care.

Discover how wireless temperature monitoring can make your hospital smarter and safer

Ensure patient safety by tracking and maintaining refrigerators and freezer temperatures, with instant notifications for temperature dips. Automate compliance with accurate reporting for regulatory standards, ensuring timely responses and consistent oversight.

Compliance Automation

Track refrigerator and freezer temperatures around the clock with instant alerts when storage conditions drift out of range. Generate compliance reports for The Joint Commission, DNV, CDC, and Vaccine for Children (VFC) audits in minutes instead of hours.

Patient Safety

Track and monitor temperature and humidity in pharmacies, laboratories, blood banks and operating rooms.

Timely Responses

Eliminate Manual Temperature Checks While Improving Patient Safety and Preventing Spoilage

Wireless sensors monitor every refrigerator and freezer continuously, alerting staff the moment temperatures drift out of range. Most hospitals recover their investment within months from reduced spoilage and staff time savings alone.

Clinical Staff

Eliminate manual temperature monitoring to streamline processes and increase compliance.

Laboratory Staff

Utilize hospital refrigeration to maintain samples, specimens, vaccines, and medications.

Cafeteria Staff

Harness automated temperature checks to meet the hospital’s refrigerator policy.

Patients

Pharmacists

Nurses

Work with confidence that patient specimens, vaccines, and medications haven’t spoiled.

Hospital Freezer Temperature Monitoring

When a compressor fails in an ultra-low freezer holding years of research samples, you have fifteen minutes before irreversible damage occurs. Standard pharmaceutical freezers behave differently. They drift slowly out of range over days, with no warning until a staff member opens the door to discover thousands in spoiled inventory.

Different freezers need different protection. Ultra-low units get aggressive rate-of-change alerts that catch degradation before catastrophic failure. Standard pharmaceutical freezers receive trend analysis that identifies subtle drift patterns. Buffered glycol probes measure the actual thermal mass of stored items rather than air temperature, eliminating false alarms every time someone opens the door.

Freezer monitoring built for high-stakes storage:

- Separate alert rules for ultra-low lab freezers and standard pharmaceutical units

- Rapid drop alerts when temperature falls faster than normal, signaling compressor failure

- Slow warm trend detection that catches gasket leaks and door seal problems days early

- Power failure monitoring with instant alerts before temperatures rise

- Document every response with timestamps and notes for regulatory audits

- Complete temperature logs even during network outages

- Planned maintenance mode for defrost cycles without triggering false alarms

Medical Refrigerator Temperature Monitoring

Insulin in the pharmacy needs different protection than reagents in the lab or platelets in the blood bank. Each type of refrigerator has its own temperature range, and what counts as an emergency varies by what’s stored inside. A two-degree drift might be acceptable for some specimens but catastrophic for vaccines.

One dashboard shows every medical refrigerator across your facility. Temperature trends reveal equipment problems before they cause loss. You catch excursions while there’s still time to move inventory to backup units. Alert thresholds adjust based on what’s stored in each location.

Medical refrigerator monitoring across your entire facility:

- Individual alert thresholds for pharmacies, labs, blood banks, and vaccine storage

- CDC-compliant buffered probes and documentation for vaccine refrigerators

- Coverage for main campus, satellite clinics, and off-site storage locations

- Alerts for both sudden failures and slow temperature drifts

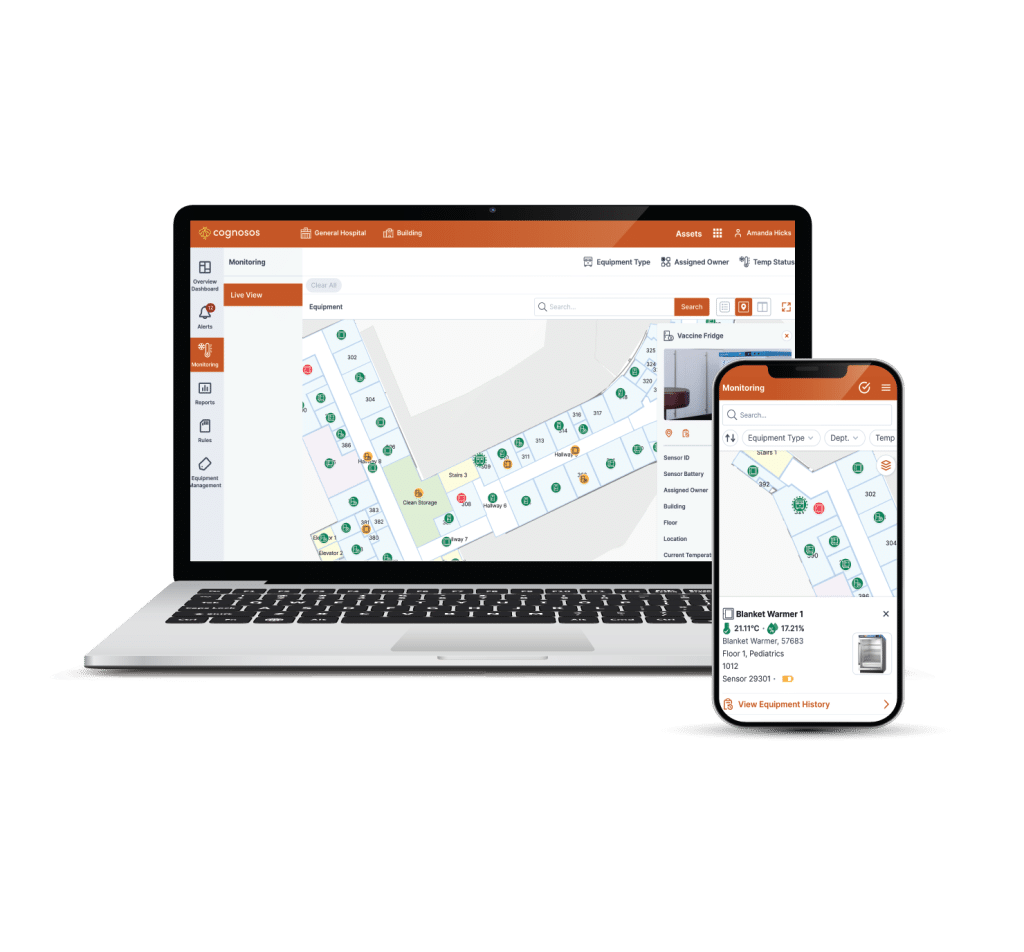

- Mobile access so on-call teams see status in real time

- Door open alerts when refrigerators stay open beyond safe timeframes

- Multiple sensor support for large walk-in refrigeration units

Cognosos Environment

Cognosos‘ hospital temperature and environmental monitoring system reduces spoilage of medications, vaccines, and food by automating temperature tracking and delivering real-time alerts when equipment malfunctions. Streamline compliance reporting, enhance patient safety, and improve staff efficiency across clinical, laboratory, pharmacy, and cafeteria operations, ensuring safe storage and timely responses to temperature fluctuations.

Cognosos Environment delivers automated monitoring designed for healthcare facilities. Help protect critical medications, vaccines, and samples with continuous 24/7 monitoring and instant alerts. Discover how Cognosos can make your hospital smarter and safer. Contact us today to see automated monitoring in action at your facility.

Request a demo

Temperature Monitoring FAQs

What is a hospital refrigerator temperature monitoring system?

A system that collects continuous readings, alerts staff to excursions, and creates audit ready logs for regulatory compliance.

What are acceptable temperatures for hospital refrigerators and freezers?

Follow your policies and device guidance. Typical ranges are published by regulatory bodies. Your policy controls acceptable ranges for your facility.

Do I need a buffered probe for vaccine storage?

Yes for most vaccine refrigerators. It reduces false alarms from brief door openings by measuring thermal mass instead of air temperature.

What is NIST traceable calibration?

Calibration that links each sensor to national measurement standards through an unbroken chain of comparisons. Certificates document the traceability path.

How long should we retain temperature logs?

Retain temperature records per hospital policy and accreditor guidance. Many facilities keep records for three to seven years to support retrospective investigations.

How does the system handle outages?

Sensors store readings locally for up to 30 days and backfill automatically once the network recovers. The audit trail documents any gaps.

How do hospitals choose a temperature monitoring system?

- Verify the system supports your specific regulatory requirements

- Confirm calibration certificates meet accreditor standards

- Evaluate alert reliability and escalation workflows that match staffing

How do hospitals monitor refrigerator and freezer temperatures 24/7?

Wireless sensors inside each unit transmit temperature readings to a cloud platform every few minutes. The system alerts staff via text, email, or phone when temperatures move outside safe ranges.

What systems alert staff to out-of-range temperatures in real time?

Cloud-based monitoring systems send instant alerts through text, email, or phone when temperatures exceed safe thresholds. Advanced systems also detect gradual drifts that signal equipment problems before complete failure.

How do you monitor medication temperature in a hospital pharmacy?

Calibrated wireless sensors inside pharmaceutical refrigerators continuously transmit readings to a monitoring platform. The system alerts staff immediately when temperatures drift outside required ranges.

What temperature should hospital refrigerators be kept at?

Most hospital refrigerators maintain 36°F to 46°F for medications and vaccines, while blood banks operate at 33°F to 42°F. Freezers range from -13°F to 14°F for pharmaceutical storage to -112°F to -86°F for ultra-low research units.

Why go with Cognosos?

Audit ready logs in one click: Generate formatted reports for any survey or inspection instantly.

Sensors with NIST traceable calibration: Every sensor ships with certificates from ISO 17025 accredited labs.

Escalations that fit on-call schedules: Alert chains match your staffing rotations and backup protocols.